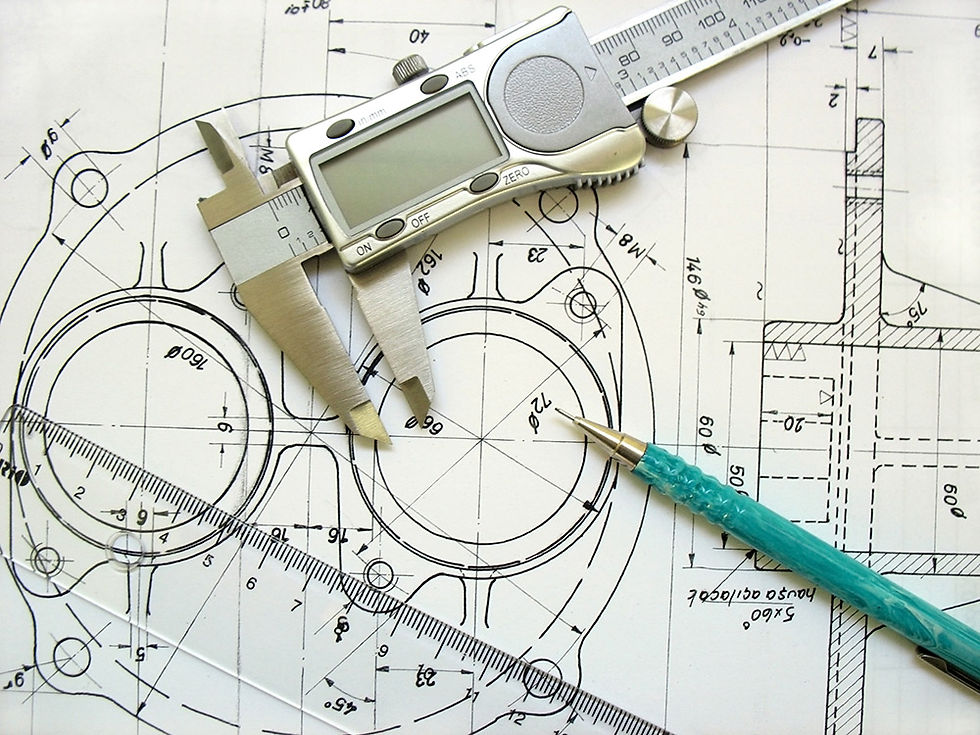

Engineering Successful Designs (HL)

Duration

14 Hours

Interconnectedness

Design in Theory | Design in Practice | Design in Context | |

| A3.2 Introduction to structural systems | B3.2 Structural systems application and selection |

Learning Intentions

Through critical thinking, practical activities and context, students will:

be able to identify simply supported beams, fixed beams, cantilever beams, continuously supported

beams, and columns, and explain their function

be able to explain how structures can be strengthened by using struts, shape, lamination and

composite materials

need to experiment with and understand how static and dynamic forces (compression, tension,

torsion, bending and shear) act within a structure. Students need to know that this can be presented

diagrammatically

explore stress-strain graphs, including Young’s Modulus, yield strength, ultimate strength and fracture and be able to describe the relationship between them. Young’s Modulus should be experimented with materials (with both high and low values) to understand how they act when stress is applied. Students should know the equation and be able to apply it

understand how a structure in equilibrium is stable and the conditions in which this is not the case

understand the reasons why structures fail, including interpreting data from finite element analysis

(FEA)

know the term “safety factor” (SF) and define it as a ratio of a structure’s absolute strength

be able to apply knowledge of SF above 1 and what this means for a structure.

Linking Questions

What ergonomic considerations should designers explore when designing and creating structures in products? (A1.1)

Which manufacturing techniques are best suited for shell and solid structures? (A4.1)

How do designers engage in modelling and prototyping when working with different classifications of structures? (B2.2)

Why is Young’s Modulus an important consideration when engaging with material selection? (B3.1)

How can a deep understanding of how forces act on structures inform the application and selection of structural systems in the real world? (B3.2)

What are the responsibilities of the designer when designing and creating safe and durable structures for products? (C1.1)

To what extent do safety factors (SFs) influence the life-cycle analysis of a structure? (C3.2)

To what extent can prototyping techniques, such as simulations of structures, be used to predict real- world performance? (A2.2)

How does a deep understanding of stress-strain graphs influence the designer’s material selection when designing products? (A3.1, B3.1)

How is the structural system of a product influenced by the mechanical and electronic systems required for the product to function? (A3.3, A3.4, B3.3, B3.4)

How does finite element analysis (FEA) play a role in modelling and prototyping? (B2.2)

To what extent is the design of a structurally safe product the responsibility of the designer? (C1.1)

What are the considerations of the designer of physical structures to ensure a positive life-cycle analysis result when designing a product? (C3.2)